As part of a larger maintenance strategy, outsourcing the diagnostics and monitoring of critical machinery can be an effective tool in the battle to maximize asset availability and plant efficiency. In situations in which machine performance is critical but in-house analysis is not practical because of limited resources, outsourcing offers a cost-effective solution. Automation and enabling technologies like IOT, Wifi enabled sensors, cloud technologies and automation help improve the ease of this diagnostic monitoring and remote maintenance services leading to improved margins and overall efficiency of the plant.

The goal of such predictive maintenance techniques is to trend and analyze equipment and component performance in a real time manner so as to predict and identify early warnings of potential failure. This helps organizations in putting together an on-demand maintenance model that helps monitor industrial machinery and equipment in real time. This deviates from traditional more expensive condition maintenance techniques where there is a periodic monitoring of assets and machinery to help ensure that the machine runs efficiently and there is no downtime. This real time on-demand approach can significantly help reduce costs of maintenance. Additionally outsourcing non-critical functions in this maintenance lifecycle to a MaaS (Maintenance -As-A-Service) model, helps organizations adopt a lean mindset and focus on what is truly important.

These MaaS Programs help our clients in focusing on leaning out and improving their predictive maintenance services while also allowing them to focus on critical insights and operational root causes that can improve reliability within their plants.

The goal of such predictive maintenance techniques is to trend and analyze equipment and component performance in a real time manner so as to predict and identify early warnings of potential failure. This helps organizations in putting together an on-demand maintenance model that helps monitor industrial machinery and equipment in real time. This deviates from traditional more expensive condition maintenance techniques where there is a periodic monitoring of assets and machinery to help ensure that the machine runs efficiently and there is no downtime. This real time on-demand approach can significantly help reduce costs of maintenance. Additionally outsourcing non-critical functions in this maintenance lifecycle to a MaaS (Maintenance -As-A-Service) model, helps organizations adopt a lean mindset and focus on what is truly important.

These MaaS Programs help our clients in focusing on leaning out and improving their predictive maintenance services while also allowing them to focus on critical insights and operational root causes that can improve reliability within their plants.

Reliability and Maintenance Services

We offer many options to help you with your maintenance services

Outsourced MaintenanceOur outsourced reliability program helps organizations outsource their maintenance and monitoring services to Ennosys. This program provides a complete package to our client that includes our IOT sensor package (EYE) and a cross functional team to ensure reliability. This program helps reduce costs, improve efficiencies while allowing internal teams to focus on improving operations and driving internal business improvements. The program also includes a team that includes domain experts, reliability engineers, IT support and monitoring experts in a geographically dispersed hybrid model. We work with our clients to meet pre-agreed service level commitments or can also provide a managed team to meet predefined support commitments. Read more about this program here

|

Supplemental MaintenanceWe bring in our experts to augment your internal programs and experts. As an extension of your team, our teams can complement your internal maintenance teams by installing our internet based sensor package (EYE) and offering the IOT and monitoring support needed in a MaaS (maintenance-as-a-service) model. This leaves your internal teams to focus on their internal maintenance commitments, improve their operations and reduce costs. Read more about this program here

|

OEM ProgramsOEMs need to maintain and manage the reliability of their installed assets and machinery at the customer plants. This program helps our clients test and measure the performance of their machinery. We help OEMs augment or improve the health of their maintenance programs that they offer to their clients. As an example we provide a "SMART Rotating Equipment" model to OEM pump, motor and generator manufacturers in a white label manner to allow them to improve the monitoring of their machinery at their clients globally

|

EYE: IIOT Monitoring Package

The Ennosys EYE is a complete Remote Monitoring Package in a Box. This includes a Sensor Box with a Monitoring Tablet and a Mobile Wifi Device. This package is pre-configured and is ready deploy at the customer site. We work with you to help install this package on your machines and train your personnel to use it. Installation is simple and it can be done by a non IT person in most cases.

Magnetically Installs in minutesThe IP68 certified sensor box installs seamlessly on your machines magnetically in minutes and enables FFT analytics from the get go

|

Immediate feedbackConnect to the included Mobile Wifi device or to your internal plant Wifi. You get immediate feedback through visual fault detecting indicators on your sensors

|

Monitor anywhereMonitor remotely and wirelessly either on our included tablet or anywhere in the world, get notified and record data

|

Industrial Sensor BoxThe Sensor Box from our product partner (Infinite Uptime) is a device that is capable of measuring tri-axial high-frequency mechanical vibrations, temperature, and acoustics. It is portable, and magnetic and can be attached to any surface, and immediately start providing mechanical data. Download the Sensor Specifications here. |

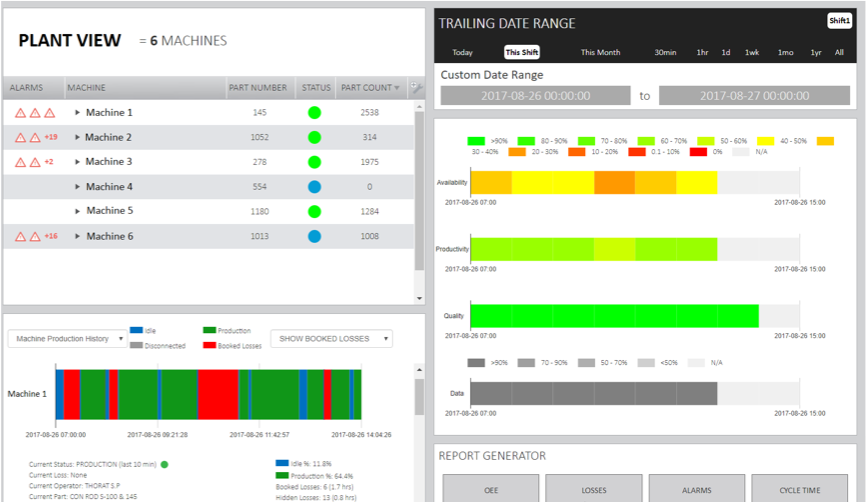

IoT PdM Monitoring ServicesThe online EYE is an configurable dashboard that can be customized to meet your reporting and analytics needs. This dashboard provides real time visibility in to your machine and plant data in a secure manner on a variety of devices. It has views to monitor both machine uptime and productivity in addition to predictive maintenance. The online dashboard supports FFT analytics, customization of alarms, parameters or other elements to meet your business needs.

|

Demo and TrialOur demo can show you an actual installation and dashboard working in real time. Ask us about our trial, we offer a FREE trail on your assets. Bring up your asset data in minutes and start to review your data in real time. Our online demos take an hour and an onsite trial can be completed in 2-3 hours.

|