Industrial Agility

Our IOT consultants comprise of a multi-skilled team that has built connected environments for our clients across the devices, product engineering, networking, messaging, edge analytics, middleware and cloud spaces. Leveraging a design thinking approach, this team has worked with clients from the ground up, to understand their needs and build a MVP (minimum viable prototype) in a couple of weeks. Our product agnostic and flexible IOT consulting approach helps us fit in with our clients' teams and be part of their IOT journey incrementally.

Predictive Maintenance

Smarter machines today are able to predict their own failures in a proactive manner. This ability to detect early warnings and anomalies helps organizations prevent failures, improve productivity and maximize overall equipment effectiveness. Ennosys' SMART Predictive Maintenance solutions help our clients in capturing and analyzing real time data from machines and then using that data to predict early warnings and failures. This has helped our clients cut maintenance costs, reduce downtime. This has allowed our clients to go from a reactive maintenance model to a proactive maintenance model where the machine self diagnoses itself and then alerts the operator about potential failures downstream. These solutions help our clients by providing real time visualization of early warnings and faults. Learn more about our Maintenance and Reliability Programs

Predictive Maintenance: Experience

Use Case: Noise and VibrationAt a manufacturer, the team worked on identifying faulty, equipment by monitoring, temperature, acoustics and vibration. Analyzing this typically results in a 20% reduction in breakdown rates by a combination of FFT and predictive analytics

|

Use Case: Cylinder VibrationA client was looking at irregular quality due to a vibrating cylinder. The problem was unstable velocities in all axes. Attaching a sensor to the cylinder allows the team to extract data to the cloud and then analyze the harmonics spectrum. This analysis was able to predict misalignments

|

Use Case: VFD CompressorAt a manufacturing company, the client was looking at the breakdown of compressors. Fan speed and other factors contributed to wear and tear. This was done by proactively monitoring vibration, temperature and other environmental factors. The effort was able to reduce breakdowns resulting in lower maintenance costs

|

Noise and Vibration

The Vibration and Noise Predictive Monitoring Solution features a SMART sensor system with edge computing. These edge sensors seamlessly plug in with client machinery to extract and port machine data. This is then connected to the cloud and enables local machine monitoring and visualization. AI/Machine Learning models are leveraged to recognize patterns in the sensor data to detect anomalies helping our clients spot anomalies and prevent costly faults before they happen

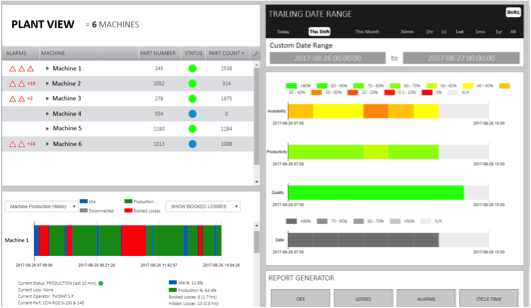

IOT PlatformEnnosys's IOT Platform directly integrates with existing machines and systems to extract sensor data. The data is then transferred to an IOT cloud-based framework, where it is analyzed and converted into meaningful intelligence in the form of easy-to-assimilate dashboards and reports. An integrated analytics framework then analyzes this data at the edge and cloud to ensure that there is real time event management, orchestration and monitoring. A rapid Decision Support System then helps analyze the data to yield insights for the customer to improve OEE and TEEP.

|

Flexible Options to Jumpstart your POC

We offer many options to help you jumpstart your IOT Monitoring Pilot

DIY TrialIn our DIY Trial ship you up-to 2 sensors free to charge for a period of 2-3 weeks. Our team helps you set this up online using phone/video calls. For a period of 2-3 weeks you get to play with our sensors and try them on your machines. Monitoring and Training support is included for this period. All you do is pay for shipping!

|

Onsite Workshop and TrialIf you want us to come out and install these sensors on your machines, we can do that too. Our discovery day for 1 day involves a "Site Walkthrough", a FREE installation, and some training to help you start to use these sensors. In addition, we offer 2-3 weeks of FREE monitoring and support! Read about our FREE IOT Trial here

|

Discovery WorkshopWe offer this option, when you are not sure what to do with the sensors. In a typical 2 days onsite engagement, our team works with your engineering teams to understand your objectives and key machines to monitor using a GQMP process. We then install the sensors, dashboards with a site walkthrough. FREE Training and Monitoring Support is also included in this package for 2-3 weeks.

|

Smart Rotating Equipment

|

Demo and TrialOur demo can show you an actual installation and dashboard working in real time. Ask us about our trial, we offer a FREE trail on your assets. Bring up your asset data in minutes and start to review your data in real time. Our online demos take an hour and an onsite trial can be completed in 2-3 hours.

|